Emergency Plumbing Situations

Plumbing emergencies occur for various reasons. Most are preventable through regular maintenance and periodic inspections of the sewer line, valves and supply lines under fixtures, water heaters, toilet insides, and piping in the attic or under the house, if accessible. It is something many of us ignore as long as the plumbing is working and flowing well. We understand that plumbing emergencies occur at the least opportune time so we are available to deal with these even when the timing is terrible.

What are the most common plumbing emergencies?

Clogs and burst pipes are the number one reasons for people to call for a plumbing emergency, for obvious reasons. Let’s look at emergency clogs, first.

No one wants to deal with raw sewage pouring into their home or business. It is nasty and an obvious health hazard. How is this prevented? What are the signs of it becoming an issue? First we need to look at how much water typically goes down our drains. When a sink faucet is used, whether a kitchen or bathroom sink faucet, it is producing around 1.0-1.5 gallons per minute (GPM) so not much water is flowing down the drain while being used. Shower heads produce about 2.2 GPMs. Bathtubs are closer to 3.5 - 4 GPMs. A toilet will use anywhere between 1.28 - 3 gallons per flush, depending on the age and design of the toilet. Clothes washers pump at a rate around 10 gallons per minute during the spin cycle for older units and 21 gallons per minute on newer, more efficient, clothes washers. All this is to say that depending on the fixture used, different volumes of water will flow through a home or business’ drain which affects when a problem drain may show signs of actually having problems.

Usually we find that when a clothes washer is used or when toilets are used is when a problematic drain will show signs of being a problem. That is because more water flow exposes the issue faster. For instance, if a sewer line that is 4” in diameter (the most common size for a residential home) has a partial separation but the separation is 30 feet down the line from where it exits the home, and is impeding water and waste flow, it will take a lot of water flowing before it fills up the line enough to cause it to back up into the home, especially if it is only partially obstructing flow. A two foot long section of a 4” diameter pipe will hold a little over one gallon of water so a 30 foot section will hold around 15 gallons, or the equivalent to a few flushes or load of laundry water draining. Another thing to consider is usually on problematic drains, they are only partially obstructed and not 100%. This means that once flow stops, the problem area has enough time between uses to allow the water to escape and everything seemingly goes back to normal. It isn’t until enough water flows that the problem becomes apparent, like if someone is showering and a load of laundry is done simultaneously. That is when panic mode can set in for the homeowner as water begins to back up into the tub or shower or gurgling noises occur in the toilet. The gurgling noise from a toilet is a sure sign of a main line clog. What is happening is air that is trapped in the sewer line, as it fills with water, escapes upstream through toilets and lower level fixtures like tubs and showers. If you hear this gurgling, stop using water immediately. Sometimes when people stop using water due to hearing gurgling, they give it a few hours before using it again and assume when the gurgling stops, the problem has fixed itself. Really, what has happened is that enough water was finally used and it exposed the issue but when that scenario happens again, the problem will come back. This is why it is a great idea every two to three years, depending on results, to have a sewer line video inspected for issues.

If you are on a septic tank with a leach field or aerobic system, they have different issues that can come about and cause similar symptoms to those mentioned above. Dynamic Drains can diagnose some of the more common issues with septic systems, but depending on what they are, they may need a licensed septic installer or company in order to deal with it. We do not pump septic tanks or grease traps. We do not install septic tanks or leach field lines as that falls under a septic installers license and is regulated by TCEQ (Texas Commission on Environmental Quality) and not the Texas State Board of Plumbers. Dynamic Drains can legally do any work up to the tank but not with the tank itself. If a septic tank is full and can not drain properly, the symptoms described above can also occur. We can determine whether or not if a septic tank is the issue, the leach field line, or if the main sewer line is the issue.

Another common residential plumbing emergency is burst pipes or leaking water heaters. How can this be prevented? There is a myriad of reasons this can happen. There are 5 types of piping material that are the most commonly used for drinking water piping. They are: copper, CPVC (chlorinated polyvinyl chloride), PVC (Polyvinyl Chloride), PEX (Cross-Linked Polyethylene) and galvanized steel. All of these are susceptible to leaks and breaks. Some have a better track record than others but much of it depends on the quality of the original install.

A burst pipe can come about unexpectedly and especially after a hard freeze. Insulating any exposed pipes is number one when protecting pipes from freezing. Heat tape can help but relies on electricity to work so if the power goes out, that protection is gone. In this part of the world, the worst freezing temperatures we get are around 20-30°. These temperatures can cause exposed pipes to freeze if it stays below 32° for 8 hours or more. The insulation available from the hardware store would be sufficient to protect pipes from freezing. A burst pipe due to a freeze will only show after the pipe has thawed so it isn’t always immediate that an issue is present. Running water slowly all night during a hard freeze can help to prevent this but it is wasteful. The pipes that are the most susceptible to bursting from a freeze are PVC, CPVC, and Copper. Insulating any exposed piping, either under a home or outside, will prevent pipes from freezing. PEX piping can still freeze, but if installed properly, will merely expand as it freezes and after thawing go back to its regular state without any splitting occurring. Galvanized piping is malleable so it can handle some of the expansion that occurs during a freeze but it can freeze and stop water from flowing. If you have galvanized piping or PEX piping, it is still a good practice to insulate the piping, just in case.

Let’s say you and your family are going out of town for the winter holidays and want to eliminate the potential for a frozen pipe or from a catastrophe due to a random water line break. The best thing to do is to turn off the water to the home, either at the meter or at the well, turn the water heater to vacation mode, and open outside hose faucets to decrease the pressure and drain the lines as much as possible. After the pressure has decreased and water has slowed down to a drip, close the faucets and put any protective covers or insulation back on any outside faucets. Open the cabinet doors below any sink that is located on an exterior wall and make sure the heat is set to at least 65° within the home. This will help to keep the home warm enough to prevent from any interior pipes freezing. If the home will be vacant through an extended period, like a month during the colder times of the year, the best option is to have the plumbing winterized. This process is quite a bit more involved and would need an on-site evaluation to determine how best to approach it.

With galvanized piping, the more common issue is corrosion. This happens over time and is due to the water quality and the quality of the galvanized pipe. The galvanized pipe manufactured after 1972 mostly came from overseas and the quality was very inconsistent. Galvanized pipe will develop internal rust and major build-up over time and can cause pin holes or pits in the pipe. If your home or business has galvanized pipes and you have poor water pressure, often the cause is simply due to a restricted pipe from rust build-up. If you notice discolored water coming from the fixtures regularly, a potential emergency may be coming. This happens because parts of the rust are breaking off inside the pipe and ending up in the fixture. This breaking off of rust from the inside of a pipe can allow for pitting that has occured within the pipe to be exposed and leak water. We have seen this in extreme cases where the pipe becomes so corroded that it is disintegrating. It is recommended to replace these pipes with a newer material like copper or PEX that will not corrode or become restricted over time. It is a good idea to visually inspect the pipes every now and then for signs of corrosion. You may not be able to see any corrosion on the outside but if you do, that is a sure sign that there is much more corrosion on the inside and action should be taken to replace it before an issue arises. An interesting thing can happen with galvanized pipe specifically. It can somewhat heal itself if a pinhole leak occurs.

A pinhole leak is just that, a pinhole on a pipe no bigger than a sewing pin thats caused by cavitation or corrosion. These leaks can take some time before being noticed depending on the pipe’s location and where the leak occurs. What can happen over time with a pinhole, on galvanized pipe specifically, is that hard water deposits or rust can fill the pinhole, thus stopping the leak if left unattended long enough. This is more common on pier and beam homes where the galvanized water lines are located under the house. With pier and beam homes, leaks on water or sewer lines can go unnoticed because the water just leaks onto the ground. It isn’t until a bad smell, a loss of water pressure occurs, or standing water is noticed that the leak is discovered. We will often get called for a broken or leaking galvanized water line on a pier and beam home and find other leaks the property owner was unaware of because the leak was not significant enough or sealed itself before it could be discovered.

Being these specific issues with galvanized pipes are hard to prevent, short of a full replacement, this is merely to educate on what can happen with galvanized pipes for water supply and is why we, and most plumbers, recommend highly against the use of galvanized pipe for water supply, regardless of where the pipe was manufactured.

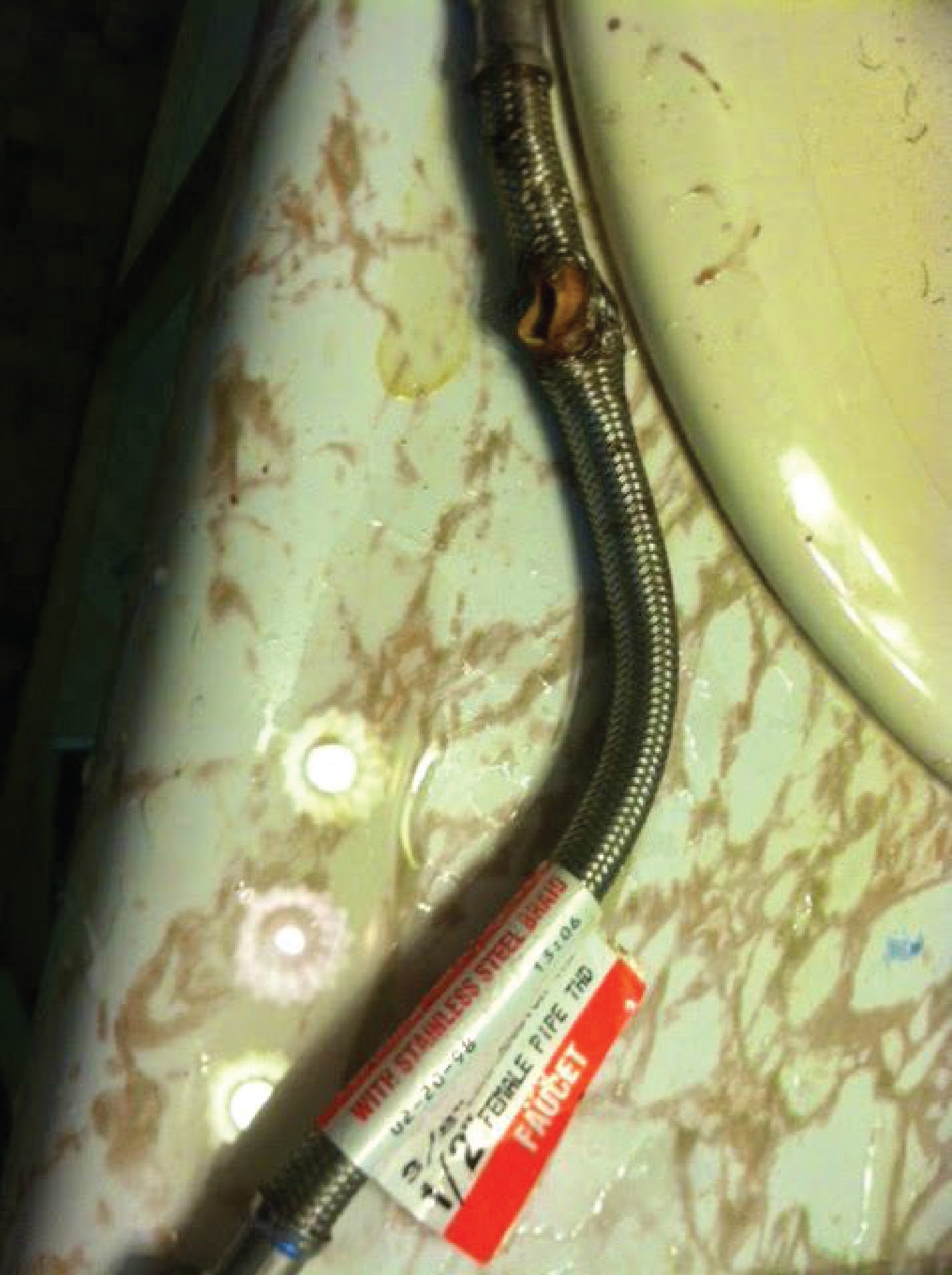

Another common burst pipe emergency occurs with the supply lines for washing machines, toilets, and sink faucets. These supply lines are the connections between the valve below the fixture and the fixture itself. The issues we see is is blistering or complete separation from the manufactured connection. The best thing to do is to check these connections every once in a while, especially on toilets and washing machines. Washing machine hoses account for most of the insurance claims for flooded homes each year in the United States. This happens because the hoses become brittle over time and the rubber hose can no longer take the pressure spike during the on and off cycle of the washer. The manufacturers of these hoses recommend replacing them every five years to keep the potential of a burst hose down to a minimum.

Commercial Plumbing Emergencies.

Clogs are also very common on commercial plumbing systems like restaurants and hotels. This requires a much more proactive approach being that a business has customers to consider and down time means lost revenue along with potential health hazards. The most common clogs we see in commercial plumbing systems is in restaurants. The types of clogs are usually due to grease build-up. Many municipalities require periodic cleaning of grease interceptors or grease traps. Often the drain lines feeding the grease interceptors are forgotten about until it is too late. Regular hydro-jetting of the grease lines is a great way to keep from emergencies occurring in a restaurant’s plumbing system. We recommend twice a year hydro-jetting if the restaurant is a place that uses a lot of oils for its cooking. Sometimes this is needed more often but it depends on the video inspection during cleaning and volume of business.

Commercial plumbing emergencies with burst water lines can occur for many reasons, usually due to excessive pressure, improper install, or even incorrect material used for the application. Urinals and commercial toilets can have failures that can cause floods or internal leaks. The best thing to do is repair leaking or noisy flushing mechanisms before they become an emergency and always use the corrects parts and a licensed plumber for performing these repairs so that there is a warranty and coverage for insurance purposes. Excessive water pressure can occur if the valve that regulates water pressure for a building fails. Not all municipally supplied water has excessive pressure that requires a pressure regulator but that can be determined by a licensed plumber and some general inspections. Anytime the main supply water pressure is above 80 psi (pounds per square inch), the plumbing code requires a pressure regulator to keep it below 80 psi. The municipality is not responsible for installation or maintenance of these valves - it is the property owner’s responsibility. Excessive water pressure can cause commercial toilet flushing mechanisms to not work or even fail. They can also cause supply lines for fixtures to burst or fail prematurely. Most plumbing fixtures, commercial or residential, work based on a pressure range of 40 - 60 psi.

As you can see, many of these types of emergencies can be mitigated through regular inspection and maintenance of a home or commercial property’s plumbing system. We do offer home and commercial plumbing check-ups as a part of our services so please do not hesitate to ask our plumbers about it.